Sustainability is becoming a more and more essential requirement for companies and here in Incomac we want to do our part too.

We have been wondering how we could actually contribute and we decided to develop a zero-emissions drying kiln, our IDV.

This is clearly a big challenge, since heat is usually necessary for the drying process and boilers and burners must be used for this purpose.

We carried out extensive research on this topic and also started a collaboration with the Department of Industrial Engineering of the University of Padua, thanks to which we are further refining a system that generates heat through “viscous dissipation”.

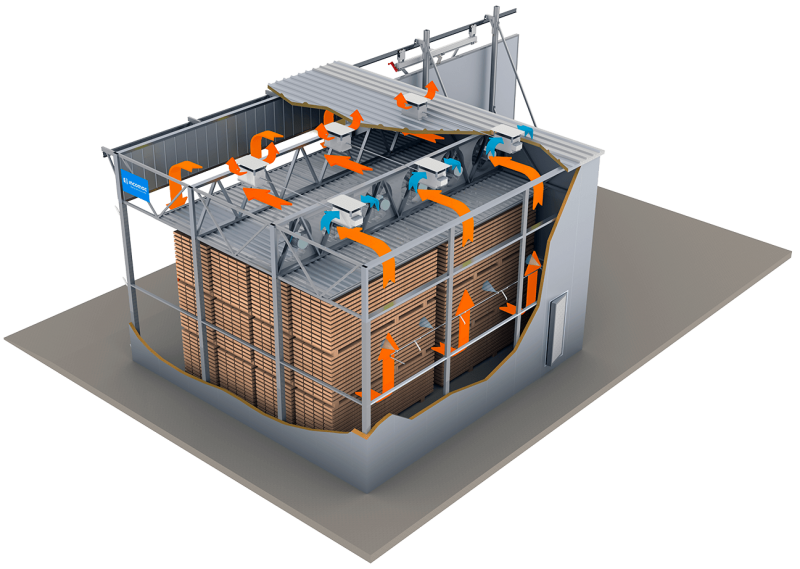

Heating through ventilation alone is based on a simple physical principle: kinetic energy of rapidly moving air transforms into heat energy as a result of the air turbulent movement and its friction on wood. The higher is the turbulence, the higher is the viscous dissipation.

When the wood heats up, the water contained in its cells evaporates. Since there are no water and steam control valves, there is no need to install a complex and expensive hydraulic system. Consequently, maintenance work on the drying kiln is minimal.

Incomac’s IDV uses clean energy, and with it, you can minimize emissions and optimize energy consumptions.

There can be no denying that our planet is unique. Reducing emissions is an essential objective of Incomac.