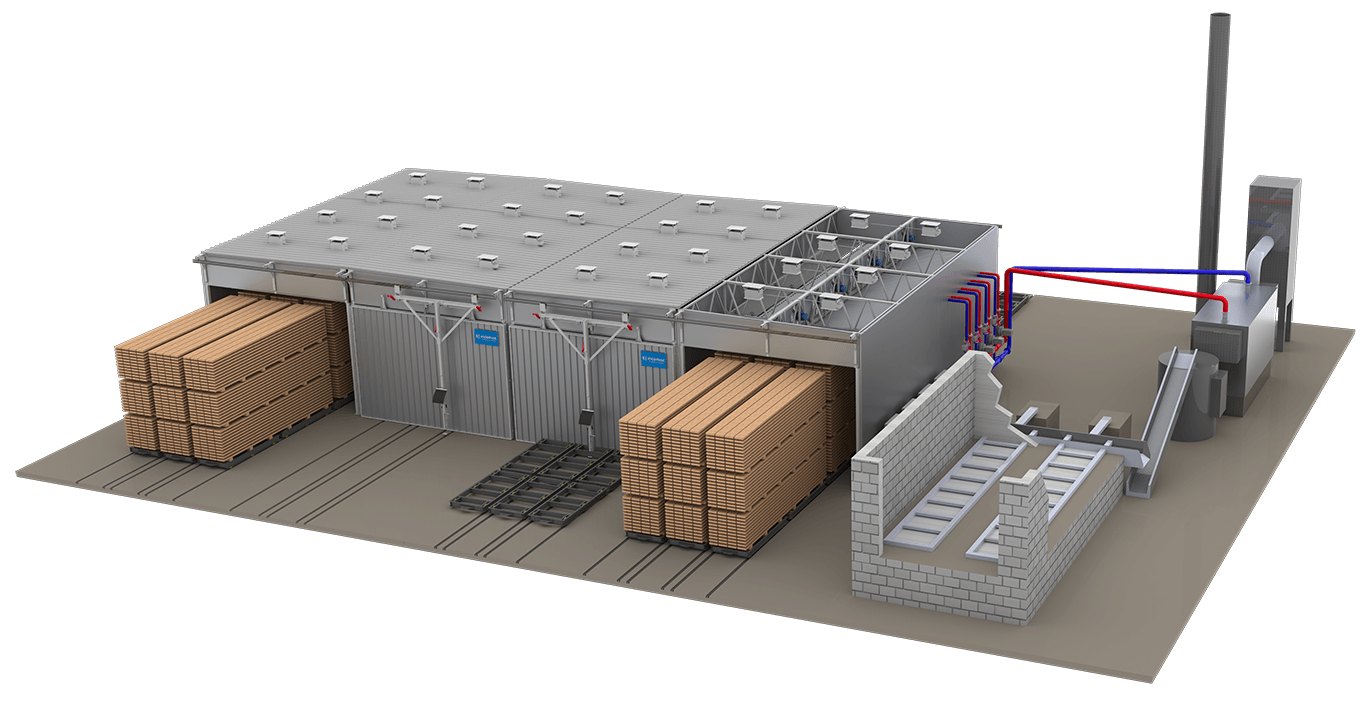

Our Research and Development Department has been designing and creating particular technologies that aim to increasingly improve performance and functionalities of our systems and it has been able to achieve significant results in terms of energy recovery and process optimization. Every system is conceived and developed to fully meet specific needs of the customer and to adapt to different weather conditions. In this way, we create the perfect balance between production and environment.

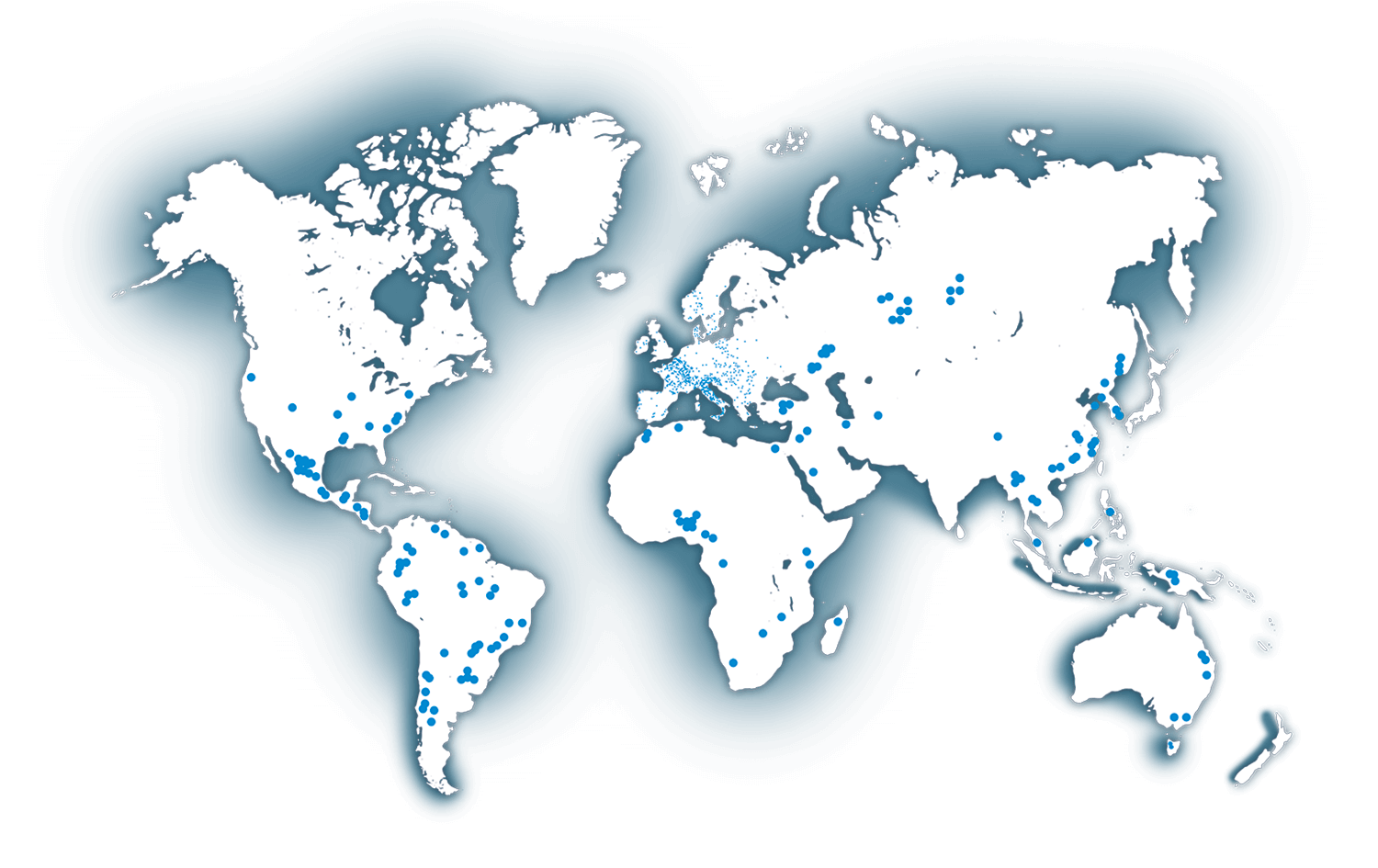

What we are today is the outcome of 45 years of work and also of what we have learned and taken advantage of in order to meet the needs of the present. In this way, we create innovation for the future. Today Incomac is synonymous with quality and experience in building wood drying systems, steaming chambers, heat treatment systems and low temperature wood storage. Our goal is to be a reference point for our clients, supporting them not only in the improvement of production performances but also in the pre- and post-sales process. We aim to be the partner you are delighted to work with, knowing that we provide high-quality service and technologies.

Choose sustainability

choose Incomac

Highly efficient solutions to make your plant more efficient and sustainable

More detailsOur history is our treasure,

our innovation-oriented

mindset is

our future

We help you choose the best drying system for your needs

We need to keep up with technology in order to preserve our solid experience and expertise in developing drying systems. We believe in the future and future developments, therefore we are always ready to make structural changes to our processes and projects. We invest in research and development in order to give the best solutions to our customers. In addition to wood drying systems, we also design and supply:

- the boiler system

- the plumbing system

- the thermal engineering